Steam, Gas & Fuel Building: Difference between revisions

No edit summary |

No edit summary |

||

| Line 24: | Line 24: | ||

| ticket_image = | | ticket_image = | ||

}} | }} | ||

The '''Steam, Gas & Fuel Building''' was located next to the [[Palace of Machinery]] and provided power for the exhibits. | The '''Steam, Gas & Fuel Building''' was located next to the [[Palace of Machinery]] and provided power for the exhibits. | ||

Latest revision as of 22:18, 9 December 2022

| File:Steam, Gas & Fuel Building.jpg | |

| Location | Main Picture |

|---|---|

| No. of Buildings | 1 |

| Architecture | |

| Dimensions | 330' x 300' |

| |

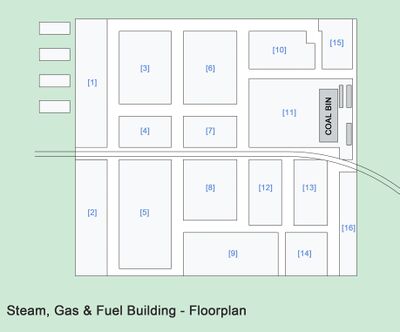

The Steam, Gas & Fuel Building was located next to the Palace of Machinery and provided power for the exhibits.

Before the Fair[edit | edit source]

Description[edit | edit source]

The steam for the operation of the various engines exhibited was generated in the Steam, Gas and Fuels building, a fireproof structure located about one hundred feet distant from the Palace of Machinery. The pipe lines, conveying the steam from the boilers to the engines and returning the condensed water back to the boilers from the condensers, occupied a tunnel seven feet broad and eight feet deep. One of these steam lines was eighteen inches in diameter, another sixteen inches in diameter, and none less than ten inches. When the boilers operated at full load they evaporated something over seven hundred thousand pounds of water per hour. This means that three hundred and fifty tons of water were hourly changed into steam, passed through the engines, returned to the form of water by passing through huge condensers, and then re-delivered to the boilers to be again transformed into live steam.

Disposing of the Smoke[edit | edit source]

Owing to the central location of the Steam, Gas and Fuels building, it would have been unsightly to avail of the tall smoke stacks required for the operation of the boilers under natural draught, consequently the draught had to be created by huge fans. The weight of this apparatus alone closely approximated three hundred tons. A number of the fans were twenty feet in diameter and for driving them independent engines were provided. To avoid the smoke nuisance the boilers were equipped with mechanical stokers. These mechanical stokers were automatically supplied with coal by a conveyor system which took the coal from the cars, crushed it and delivered it into ten and twenty ton hoppers directly in front of the various batteries of boilers.

Notable Exhibits[edit | edit source]

The exhibitors' boilers have a rated capacity of more than fifteen thousand boiler horse power, this being provided by a number of different varieties, but all of the water tube type.

Aultman & Taylor[edit | edit source]

The largest installation was that made by the Aultman & Taylor Machinery Company, who furnished sixteen horizontal and three vertical Cahall boilers with a total rating of over eight thousand horse power. The horizontal boilers were installed in batteries of two each; two of these batteries are designed for a steam pressure of 225 pounds per square inch and supply steam for the operation of the turbines, the steam being delivered at throttles with pressure of 185 pounds.